metal fabrication processes Metal fabrication is the art and science of building metal structures by cutting, bending, and assembling processes. This intricate craft involves transforming raw metal materials into pre-designed shapes and products, . Finding the upper level Junction Box in The Wells in Starfield In The Wells, you need to find a bar called Jake’s, which is located right underneath the quest marker for the Junction Box. Jake’s has a red “J” logo and has a few different entrances and exits.Marvel Spiderman - Wheels within Wheels - Find and Activate Junction box puzzle.Join Amazon Prime for Free : https://amzn.to/33mM7AsBuy External PS4 Game Dri.

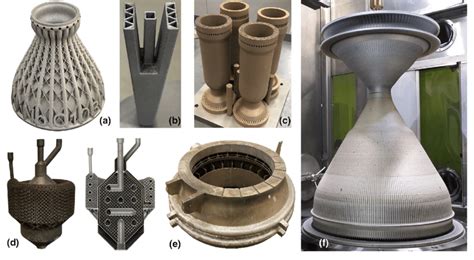

0 · your examples of fabricated parts

1 · what are fabricated metal products

2 · sheet metal assembly techniques

3 · manufacturing processes for metals

4 · manufacturing methods for metals

5 · manufacture of fabricated metal products

6 · different types of metal fabrication

7 · basic metal fabrication

Shop for steel sheet at America's Metal Superstore. Largest selection of Hot Rolled Steel Sheet, Cold Rolled Steel Sheet, Galvanized Steel Sheet at wholesale prices. Any Quantity, Any Size, .

your examples of fabricated parts

Have you ever stopped to ponder how metal is shaped, formed, and treated? That broad definition can be summed in three words: metal .• Cutting is done by sawing, shearing, or chiselling (all with manual and powered variants); torching with handheld torches (such as oxy-fuel torches or plasma torches); and via numerical control (CNC) cutters (using a laser, mill bits, torch, or water jet). • Bending is done by hammering (manual or powered) or via press brakes, tube benders and similar tools. Modern metal fabricators use press brakes to coin or air-bend metal sheet into form. CNC-controlled backgauges use hard stops to p.

The metal fabrication process encompasses manufacturing techniques like bending and cutting, using an array of advanced equipment to produce complex metal shapes, components, and .

steel ball run bunko box

Metal fabrication is the art and science of building metal structures by cutting, bending, and assembling processes. This intricate craft involves transforming raw metal materials into pre-designed shapes and products, .Metal fabrication is a manufacturing process used to shape metal into parts or end products. It usually consist of three phases: 1) design, where shop drawings are created to the intended measurements; 2) fabrication, which involves . At its core, industrial metal fabrication is a multi-step process that involves transforming raw metal into products used in construction, machinery, transportation, and . Metal fabrication is the process of turning raw metals into pre-made shapes for assembly use. For example, the panels that comprise the frame of an automobile are made through custom metal fabrication processes, which .

Learn about the material properties of hard and soft metals as well as the machining, molding, and 3D printing processes used to manufacture metal parts.Metal fabrication is vital to countless types of projects, fulfilling the need for custom, durable, and cost-effective production. Different types of metal fabrication processes include cutting, folding, welding, machining, punching, and .

In the ever-evolving world of metal fabrication, staying informed on industry advancements and trends is crucial for success.This blog post will delve into various aspects of this dynamic field, offering valuable insights to current and prospective electric vehicle owners, DIY enthusiasts, and metal fabricators alike.. We’ll explore the fundamentals of common metal fabrication processes . Key Processes in Metal Fabrication. Metal fabrication involves a variety of techniques that transform raw metals into finished products. These processes include cutting, stamping, welding, extrusion, forging, and casting. Each stage of the metal fabrication process is crucial in creating a final product tailored to specific requirements.

Cutting: One of the primary processes in metal fabrication, cutting transforms a metal sheet or block into specific shapes or sizes. There are various methods employed based on precision, material type, and desired finish. Laser Cutting: . Metal fabrication, a cornerstone of modern manufacturing, intricately shapes our world. This comprehensive guide delves deep into the realm of metal fabrication, exploring its definition, historical evolution, and the intricate processes that transform raw metal into diverse, complex structures. What are Different Types of Metal Fabrication Process? Metal fabrication involves different processes such as cutting, casting, folding, welding, machining, punching, shearing, and stamping. Let's know in detail about these metal fabrication processes - 1. Cutting. It is the most commonly used metal fabrication process. The metal is clamped in this operation between a die and a punch, with the punch folding the metal in a straight line. Making box shapes, enclosures, or any item requiring a neat, exact bend will find folding helpful.

Sheet metal fabrication is the process of forming flat metal sheets into the desired parts and products by cutting, folding, bending, and assembling. There is an extensive range of metal materials that are suitable for various sheet metal fabrication processes, including steel, aluminum, stainless steel, brass, copper, and zinc.The sheet metal fabrication process is an intricate journey from raw metal to a finished product. It involves various steps, ensuring the final product meets specific standards and functions. In this article, we’ll explore the nine vital steps in sheet metal fabrication, providing valuable insights for businesses and industry professionals. .

Metal fabrication is the process of producing metal elements from raw materials through actions like cutting, bending, welding, machining, and assembling. Many tasks are now automated, with precision machinery achieving greater accuracy than human labor. Fabrication covers making items from small springs to large architectural components .

Sheet metal fabrication is the process of forming metal sheets to the desired shape using different manufacturing methods. The completion of a product usually comprises of many steps – from cutting and bending to surface treatment and assembling. Often times a variety of fabrication techniques can be used to achieve a similar end result.

Extrusion is a metal fabrication process that produces prismatic forms like pipes/tubes, window frames, railings, casings, etc. The process works by forcing the raw material through an orifice, which gives the product its required cross-sectional shape. While going through the orifice, the metal plastically deforms (permanent deformation) into . Generally, the metal fabrication process works in the following three steps: Step 1. Designing: A few decades ago, designing in metal projects was done on paper with diagrams. This is still followed today but only for the most basic requirements. Most metal fabricators start with a design created on a computer using a dedicated software called . Metal fabrication is the creation of metal parts or structures from a variety of metal materials through different processes. The metal materials come in sheet, bar, plate, or other forms and can be made into specific shapes and dimensions. Metal fabrication needs a thorough plan and strategy to ensure the success of actual work.The different types of metal fabrication processes are applied onto a metal raw material in order to produce metal products for a variety of uses. While some of these processes employ the use of a constant application of electrical, or heat energy, some processes simply require physical manipulation in different levels, or degrees.

Stamping is a metal fabrication process you might not think about, but it's everywhere around you. It involves pressing flat metal sheets into a desired shape or design using a stamp or die. Think about the metal parts in cars, appliances, and even your electronic devices. Many of these started as a flat sheet and were shaped through stamping. In this video, we walk you through every stage of the metal fabrication process, including design, fabrication, finishing, and assembly. Tim Heston, The Fabricator's senior editor, has covered the metal fabrication industry since 1998, starting his career at the American Welding Society's Welding Journal. Since then he has covered the full range of metal fabrication processes, from stamping, bending, and cutting to grinding and polishing.

Casting and Molding: Adding Volume to Metal Fabrication. For large-volume production, machined parts are often transitioned to casting or molding processes. Metal injection molding, or MIM, is the process whereby metal powders such as nickel steel, 316 stainless, 17-4 PH or chrome-moly are mixed with a binder composed of wax and thermoplastic. Metal fabrication consists of processes used to produce products, components and structures from raw metals. Item or items created by these processes are often known as fabrications. Manufacturing companies perform metal fabrication using a combination of manual and automated processes. With these processes, they convert raw metals into metal .

Metal fabrication, transforming raw metal into finished products, has evolved remarkably. What once relied heavily on manual labour and traditional techniques such as metal flattening, bending, and forming has been revolutionised by mechanical automation in modern metal fabrication workshops. Wrightform take a quick look into the journey of metal fabrication, . Understanding metal fabrication processes is crucial for undertaking metal fabrication projects. Each process offers unique capabilities and applications that cater to specific needs.

Geometry of the part Metal fabrication is the process of cutting, bending, and assembling metal materials to create structures or products, often used in industries like construction, automotive, and manufacturing.This critical process involves several techniques such as welding, machining, and forming, and typically starts with raw materials like sheet metal or metal rods.

Sheet metal fabrication is the process of transforming sheet metal (< 1/4” thick) into finished products, structures, and components. From household appliances to transportation, commercial equipment to construction, sheet metal fabrication is critical to modern manufacturing. In this article, we cover the basics of sheet metal fabrication, from material selection to key .

Types of Metal Fabrication Processes. There are various processes involved in metal fabrication. The specific combination of metal or stainless steel fabrication processes will vary with the geometry of the part, the type of usage it will get and what it is made of. Here are examples of some choices for different types of fabrication processes:With our unmatched diverse capabilities and a broad range of metal casting processes, we are relentless about working with our customers through their entire product journey – from design to delivery. Offering these capabilities on-site through our multiple locations helps meet customer needs through reduced lead times, cost, and process variability.HVAC sheet metal fabrication is a crucial part of this process, as it involves creating the ductwork, vents, and other components necessary for heating, ventilation, and air conditioning systems. Quality and precision are paramount in ensuring the efficiency and safety of HVAC systems.

steel box beam grainger

Shop for Copper Sheet & Plate at America's Metal Superstore. Largest in stock selection of 110 copper sheet, plate at wholesale prices. Any Quantity, Any Size, Delivered Anywhere! Buy just what you need online.

metal fabrication processes|your examples of fabricated parts